Introduction

Production management software plays a critical role in helping manufacturers streamline operations, manage resources, and stay competitive in today’s fast-paced markets. From tracking inventory and orders to optimizing scheduling and production workflows, this software provides manufacturers with the tools they need to increase efficiency and reduce costs.

By integrating core functions like inventory management, production planning, and order tracking into a centralized platform, production management software ensures that all aspects of manufacturing work together seamlessly. It reduces manual errors, improves data accuracy, and offers real-time insights that help manufacturers make informed, data-driven decisions.

Choosing the right software is crucial for businesses looking to stay ahead. Whether you’re a small business or a large-scale manufacturer, the software must align with your specific needs, whether that’s ease of use, scalability, or real-time tracking. Below, we’ll explore the eight best production management software solutions available in 2025, each designed to cater to different types of manufacturing operations.

Why Choosing the Right Software Matters

Not all production management software is created equal. Different industries and business sizes have unique demands, and the software you choose should cater to those specific needs. Small manufacturers might prioritize ease of use and cost-effectiveness, while larger enterprises need scalability and advanced features like multi-location support, real-time data tracking, and comprehensive ERP capabilities.

When selecting production management software, consider factors such as:

- Scalability: Can the software grow with your business?

- Ease of integration: Does it integrate with existing tools like accounting software, CRM systems, or e-commerce platforms?

- User interface: Is the platform intuitive and easy for your team to adopt?

- Real-time data visibility: Does it provide insights into inventory, orders, and production status at any given time?

- Cost-effectiveness: Are the pricing plans within your budget without sacrificing essential features?

By keeping these factors in mind, you can ensure that the software you choose aligns with your business goals, helping you optimize your production processes and improve overall operational efficiency.

Top 9 Production Management Software for 2025

monday.com

Overview:

monday.com is a versatile work management tool that has evolved to offer robust solutions for production and inventory management. Its customizable interface and powerful automation features make it suitable for manufacturers looking for flexibility in managing production workflows. The software integrates well with a variety of tools and can be tailored to fit different production processes.

Top Features:

✅ Customizable dashboards for real-time data visibility.

✅ Visual workflows for production task tracking.

✅ Inventory and resource management through integrations.

✅ Collaborative task management for cross-department teams.

Top Benefits:

monday.com offers a highly customizable platform that adapts to different workflows, making it versatile across various industries, including manufacturing. Its strong automation capabilities reduce manual tasks, improving efficiency and productivity. The intuitive interface allows teams to easily collaborate and stay on the same page across departments, ensuring that production timelines and deliverables are met. Additionally, monday.com’s extensive integration options with other tools like CRM and ERP systems help centralize data, which boosts decision-making by providing better visibility into every stage of production.

Why It’s Recommended:

monday.com’s flexibility and user-friendly interface make it an ideal choice for manufacturers who need to adapt their workflows quickly. Its strong integration capabilities allow teams to centralize production management and collaborate more effectively.

Pros and Cons:

Positive

✅ Easy to customize

✅ Excellent team collaboration

✅ Powerful automations

✅ Integrates with CRM/ERP systems

Negatives

❌ Advanced features via integrations

❌ May require third-party tools.

❌ Higher cost for large teams

❌ Limited native production tools

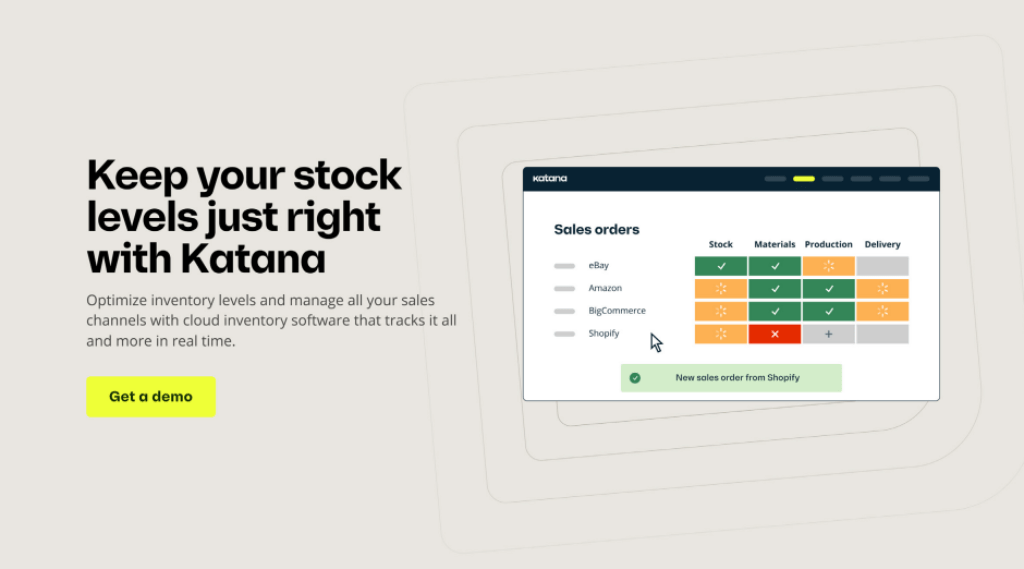

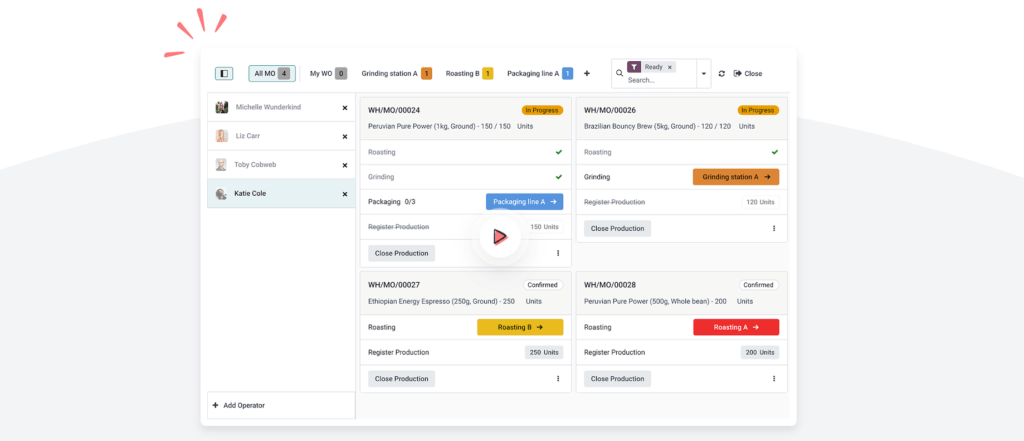

Katana Manufacturing ERP

Overview:

Katana Manufacturing ERP is a powerful production and inventory management tool designed specifically for small to medium-sized manufacturers. It offers real-time inventory updates and a visual production schedule that makes it easy for businesses to plan their production processes. Katana stands out for its seamless integration with e-commerce platforms, making it an excellent choice for businesses selling products online.

Top Features:

✅ Real-time inventory tracking and automation.

✅ Visual production schedule for easy workflow management.

✅ Bill of materials (BOM) management to streamline the production process.

✅ Seamless integration with e-commerce platforms like Shopify and WooCommerce.

Top Benefits:

Katana Manufacturing ERP shines in its ability to provide real-time visibility into inventory and production processes, which allows businesses to make instant adjustments when needed. Its visual production scheduling is user-friendly and helps manufacturers easily track orders and deadlines. The seamless integration with e-commerce platforms like Shopify and WooCommerce is a game-changer for businesses with online sales, ensuring that production planning aligns with sales demand. Katana’s automation features reduce manual errors and increase efficiency by syncing inventory, production, and sales in real time.

Why It’s Recommended:

Katana’s focus on small to medium-sized manufacturers, combined with its ease of use and powerful e-commerce integration, makes it perfect for businesses that need real-time inventory control and simplified production workflows.

Pros and Cons:

Positive

✅ User-friendly interface

✅ Excellent e-commerce integration

✅ Strong inventory automation

✅ Affordable for SMBs

Negatives

❌ Limited customization for large businesses

❌ Not suitable for complex operations

❌ Some features require integration

❌ Not ideal for enterprise-level scalability

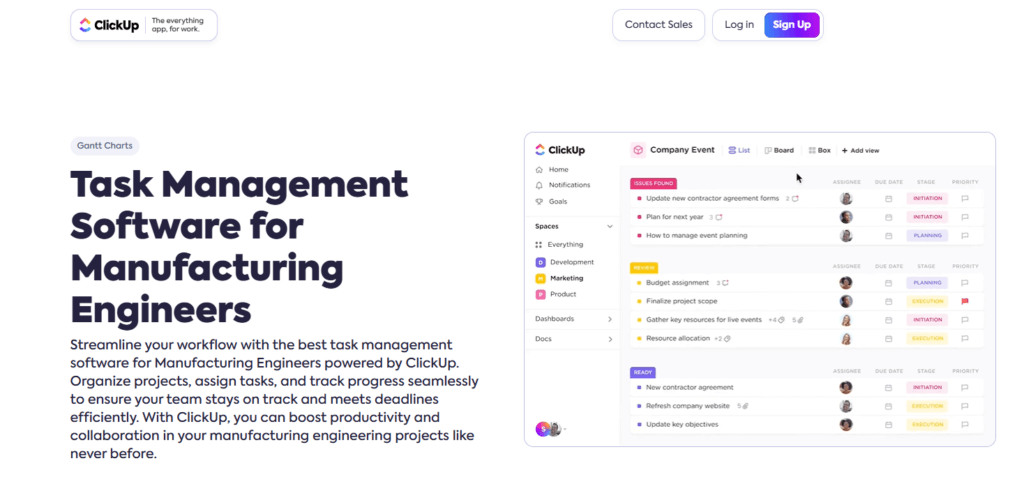

ClickUp

Overview:

ClickUp is a versatile work management tool designed to streamline operations across various industries, including manufacturing. With its highly customizable task and project management features, ClickUp empowers manufacturers to optimize production planning, track inventory, and improve collaboration among teams. Its flexibility makes it suitable for manufacturers of all sizes, allowing users to create workflows tailored to their specific production processes. ClickUp also integrates seamlessly with other tools, making it a powerful addition to any manufacturing operation.

Top Features:

✅ Customizable workflows for production planning and scheduling.

✅ Task and project management with real-time tracking.

✅ Inventory and resource management through integrations.

✅ Advanced reporting and analytics for data-driven decision-making.

Top Benefits:

ClickUp stands out for its adaptability, allowing manufacturers to design workflows that align with their unique production processes. Its real-time tracking and reporting features ensure that teams can monitor progress and address issues quickly, reducing downtime. The collaboration tools enhance communication across departments, ensuring that production stays on schedule. Additionally, ClickUp’s integration capabilities enable manufacturers to connect it with inventory and resource management systems, creating a centralized hub for operations.

Why It’s Recommended:

Pros and Cons:

Positive

✅ Highly flexible and customizable

✅ Integrates with popular manufacturing tools

✅ Scalable for businesses of all sizes

✅ Real-time tracking and reporting

Negatives

❌ Learning curve for new users

❌ Requires setup to tailor workflows

❌ Limited built-in manufacturing-specific features

❌ Overwhelming for very small teams

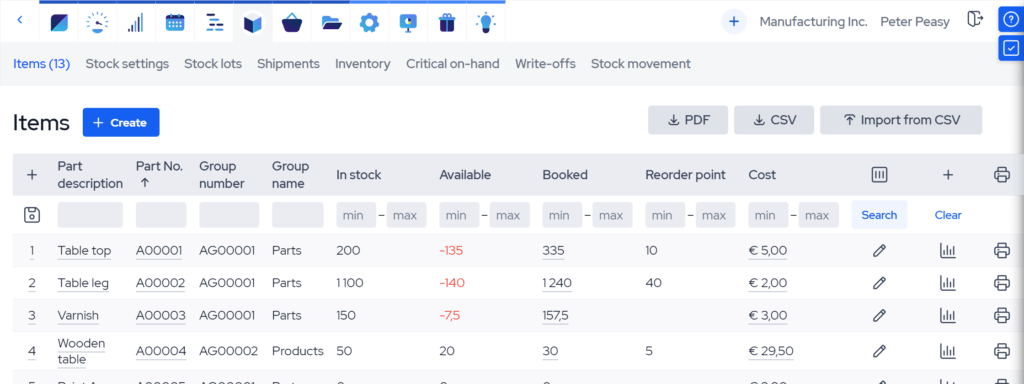

MRPeasy

Overview:

MRPeasy is a robust cloud-based ERP and MRP solution designed for small and medium-sized manufacturers. It excels in production planning, inventory management, and customer relationship management (CRM). MRPeasy offers a comprehensive suite of tools that allow manufacturers to handle everything from procurement to demand forecasting in a single platform.

Top Features:

✅ Advanced materials requirements planning (MRP).

✅ Real-time production control and order tracking.

✅ CRM for managing customer relationships and orders.

✅ Inventory management and procurement tools.

Top Benefits

MRPeasy stands out with its robust MRP and ERP functionalities, which are tailored to the needs of growing manufacturers. Its comprehensive approach, combining production planning, inventory management, and CRM in one tool, ensures a smoother flow of operations from procurement to sales. The real-time production tracking and forecasting features help businesses avoid overproduction and stockouts, ensuring better resource allocation. Additionally, the cloud-based nature of MRPeasy allows for remote access, making it easier for teams to stay connected regardless of location.

Why It’s Recommended:

MRPeasy is an excellent choice for manufacturers in the growth phase. Its combination of MRP and CRM functionality allows businesses to efficiently manage production planning and customer relationships in one platform.

Pros and Cons:

Positive

✅ Robust MRP features

✅ Combines CRM and production

✅ Great for growing manufacturers

Negatives

❌ Steep learning curve

❌Complex setup for beginners

❌Limited scalability for large enterprises

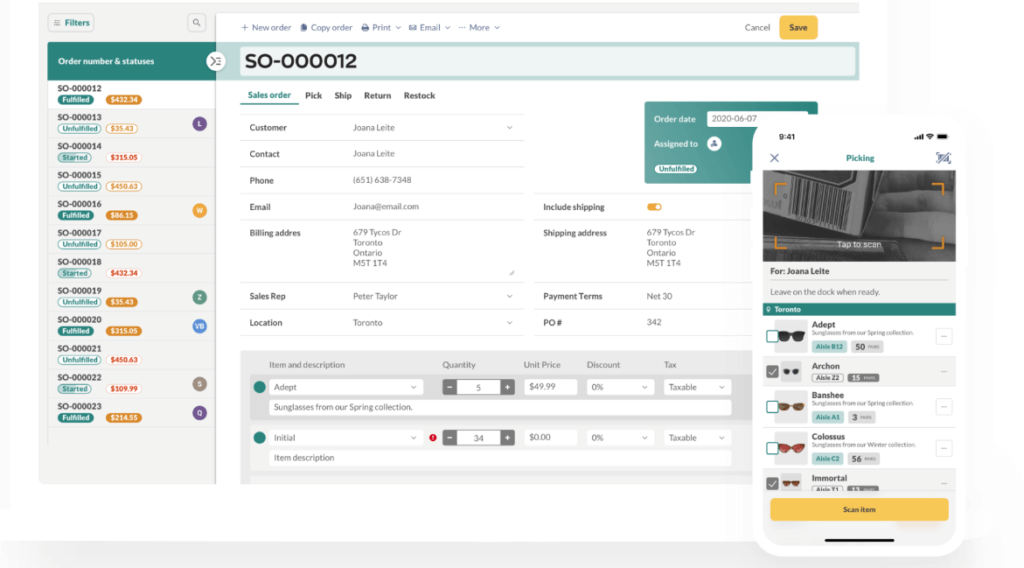

inFlow Inventory

Overview:

inFlow Inventory is an inventory and order management software designed to support manufacturers and distributors in managing stock and tracking orders. Its intuitive interface and powerful features make it a go-to choice for small manufacturers who need a straightforward solution for managing their inventory without the complexities of a full ERP system.

Top Features:

✅ Inventory control with barcode scanning and order tracking.

✅ Customizable reports for real-time stock updates.

✅ Integration with accounting software such as QuickBooks.

✅ Multi-location inventory management for companies with several warehouses.

Top Benefits:

inFlow Inventory’s biggest advantage is its simplicity and ease of use, making it accessible even for businesses with limited technical experience. It offers a highly intuitive interface that simplifies inventory tracking and order management. With barcode scanning and real-time stock updates, manufacturers can reduce errors and ensure accurate inventory counts, which in turn leads to better production planning. The software’s affordable pricing makes it an attractive option for small businesses, while its ability to integrate with popular accounting tools like QuickBooks ensures a seamless workflow between financial and inventory management.

Why It’s Recommended:

inFlow Inventory is perfect for small-scale manufacturers who need a simple, easy-to-use solution for managing inventory and orders without diving into the complexities of a full ERP system. Its affordability and ease of use make it accessible to businesses looking to improve inventory management without breaking the bank.

Pros and Cons:

Positive

✅ Easy to use

✅ Affordable pricing

✅ Great for inventory control

✅ Barcode scanning support

Negatives

❌ Limited production planning features

❌ Not suitable for large-scale manufacturers

❌ Lacks full MRP capabilities

❌ Basic reporting for advanced needs

Fishbowl Manufacturing

Overview:

Fishbowl Manufacturing is a comprehensive manufacturing and inventory management tool that caters to manufacturers and wholesalers. It offers in-depth inventory control along with advanced manufacturing functionalities, allowing businesses to manage their production processes and stock efficiently from a single platform.

Top Features:

✅ Detailed inventory tracking and control across multiple locations.

✅ Automated purchasing and sales order management.

✅ Barcode scanning for fast and accurate data entry.

✅ Customizable manufacturing workflows for production planning.

Top Benefits:

Fishbowl Manufacturing’s top benefit is its deep inventory management capabilities, which are ideal for manufacturers with complex logistics and multi-location operations. The software provides detailed tracking of inventory across multiple warehouses, ensuring stock accuracy and reducing wastage. Its customizable workflows allow manufacturers to design production processes that suit their unique needs, offering flexibility in production planning. Fishbowl’s barcode scanning features also speed up data entry, improving the accuracy and efficiency of order fulfillment, and automating repetitive tasks like purchasing and sales orders ensures businesses stay on top of demand.

Why It’s Recommended:

Fishbowl Manufacturing’s strength lies in its ability to provide advanced inventory control alongside customizable workflows for production. It’s ideal for manufacturers with complex logistics needs who require multi-location inventory management and streamlined production planning.

Pros and Cons:

Positive

✅ Strong inventory control

✅ Multi-location support

✅ Customizable workflows

✅ Affordable for growing manufacturers

Negatives

❌ Dated user interface

❌ Steeper learning curve

❌ Limited e-commerce integrations

❌ Slower updates on new features

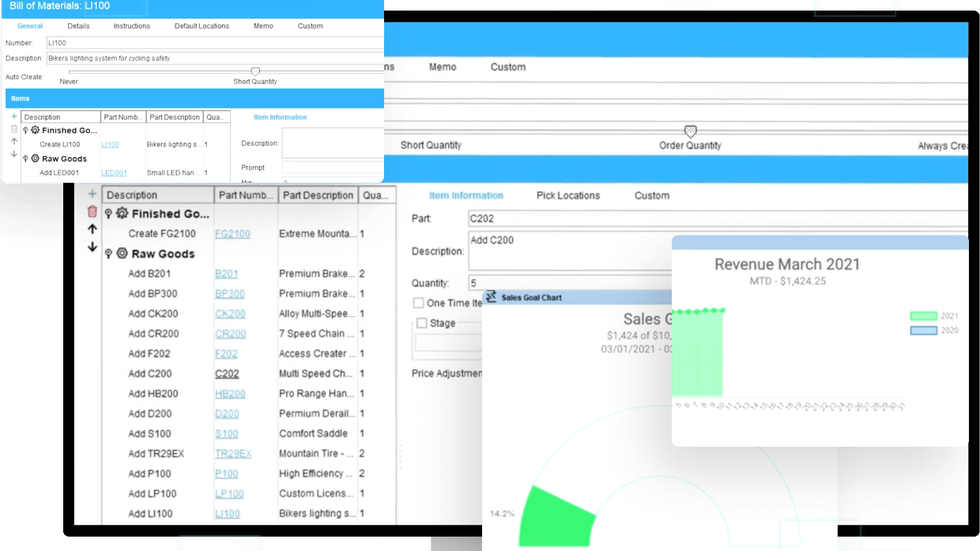

Odoo Manufacturing

Overview:

Odoo Manufacturing is an open-source ERP platform with a comprehensive manufacturing module designed to meet the needs of businesses that require customization and flexibility. With tools for materials requirements planning (MRP), scheduling, quality control, and more, Odoo offers a highly adaptable solution for manufacturers looking to tailor their software to their specific workflows.

Top Features:

✅ MRP and production scheduling for efficient planning.

✅ Bill of materials (BOM) management and product lifecycle management (PLM).

✅ Integration with other Odoo modules (e.g., accounting, CRM, inventory).

✅ Quality control tools to ensure product standards.

Top Benefits

Odoo Manufacturing’s primary benefit lies in its open-source flexibility, allowing businesses to fully customize the platform according to their specific needs. The software’s comprehensive suite of ERP tools, including MRP, production scheduling, and quality control, makes it a one-stop solution for manufacturers looking for end-to-end management. The scalability of Odoo is another major advantage; businesses can start with the basic modules and expand as their needs grow, all while integrating seamlessly with other Odoo apps like accounting, HR, and CRM. This modular structure ensures that manufacturers get a fully tailored solution without paying for features they don’t need.

Why It’s Recommended:

Odoo Manufacturing is best suited for businesses with complex and specific needs that require a customizable ERP platform. Its open-source nature allows manufacturers to tailor the software to their exact workflows, making it an excellent choice for large-scale manufacturers who need flexibility and scalability.

Pros and Cons:

Positive

✅ Highly customizable

✅ Extensive ERP features

✅ Scalable for large operations

✅ Open-source flexibility

Negatives

❌ Requires technical knowledge to customize

❌ Potentially high implementation costs

❌ Can be overwhelming

❌ Complex setup

NetSuite Manufacturing

Overview:

NetSuite Manufacturing is a cloud-based ERP system that offers comprehensive manufacturing and supply chain management capabilities. It’s particularly suited for large manufacturers needing enterprise-level tools to manage multi-location operations, complex supply chains, and global logistics. NetSuite provides advanced features like real-time production control, financial management, and automated supply chain planning, making it an all-in-one solution for manufacturers with large-scale operations.

Top Features:

✅ Comprehensive production control and automation tools.

✅ Real-time visibility into inventory, production, and financials.

✅ Global scalability with multi-location and multi-currency support.

✅ Advanced supply chain management and demand forecasting.

Top Benefits

NetSuite Manufacturing’s top benefit is its scalability and ability to support large, multi-location manufacturing operations. It provides real-time insights into production and inventory levels, which improves decision-making and helps avoid production delays or stockouts. The integrated financial and supply chain management tools ensure that all parts of the business work together seamlessly, reducing inefficiencies. Its global capabilities, including multi-currency and multi-location support, make it ideal for manufacturers with operations across various regions. For enterprises needing a solution that scales with business growth, NetSuite is an excellent option.

Why It’s Recommended:

NetSuite Manufacturing is recommended for large-scale and enterprise manufacturers that require a robust, scalable ERP system capable of managing complex operations across multiple locations and regions. It’s an all-in-one solution for production, financials, and supply chain management that ensures manufacturers have full visibility and control over their processes. NetSuite’s real-time reporting and global capabilities make it indispensable for businesses operating on a large scale.

Pros and Cons:

Positive

✅ Enterprise-level functionality

✅ Real-time production monitoring

✅ Comprehensive financial management

✅ Scalable for large operations

Negatives

❌ Expensive for small businesses

❌ Complex implementation process

❌ Steep learning curve

❌ Overwhelming for simple operations

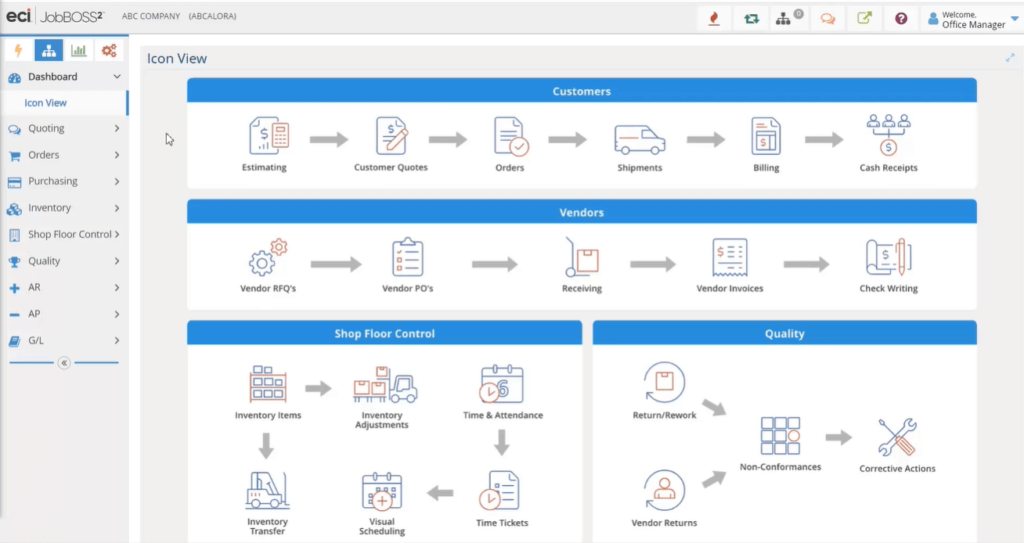

JobBOSS

Overview:

JobBOSS is a job shop management software that is designed to help custom manufacturers streamline their production processes. It combines job costing, quoting, production scheduling, and inventory management, providing a well-rounded solution for businesses with custom, on-demand production workflows. The software is highly customizable, allowing manufacturers to tailor workflows to suit the unique demands of each job, making it especially useful for job shops with fluctuating production schedules.

Top Features:

✅ Job costing and quoting tools for accurate pricing.

✅ Customizable workflows for job tracking and scheduling.

✅ Real-time data on work orders, materials, and shop floor activities.

✅ Inventory control and resource allocation for on-demand production.

Top Benefits

The top benefit of JobBOSS is its flexibility for manufacturers with custom and on-demand production workflows. The software allows for highly accurate job costing and quoting, ensuring that manufacturers can price jobs correctly and avoid underestimating project costs. Its real-time job tracking feature keeps teams updated on production status, allowing them to make adjustments as needed. JobBOSS is also highly adaptable, giving job shops the freedom to create workflows that align with their specific production processes. This flexibility makes it an ideal solution for businesses that handle custom orders with varying timelines and requirements.

Why It’s Recommended:

JobBOSS is recommended for custom manufacturers and job shops that need adaptable, on-demand production management software. Its ability to provide accurate job costing and real-time tracking makes it perfect for businesses that handle custom projects with fluctuating deadlines. JobBOSS’s flexibility in designing workflows for unique jobs ensures that manufacturers can tailor the software to meet the specific demands of their production processes, making it invaluable for those with complex or varied orders.

Pros and Cons:

Positive

✅ Excellent for custom workflows

✅ Real-time job tracking

✅ Easy job costing and quoting

✅ Adaptable for job shops

Negatives

❌ Limited advanced MRP features

❌ Not suited for mass production

❌ Requires customization for optimal use

❌ It can be expensive for small shops

Factors to Consider

Selecting the right production management software can be overwhelming with so many options available. Each tool offers different capabilities, features, and pricing models. However, by understanding the core functionalities of production management software and focusing on the factors that matter most to your business, you can narrow down your options and make an informed decision.

Understanding Production Management Software

Production management software helps manufacturers streamline the process of production planning, inventory control, order tracking, and resource allocation. These tools provide a centralized platform that integrates core business functions to improve operational efficiency. From managing raw materials to scheduling production jobs, the software ensures that all parts of the manufacturing process are running smoothly and in sync.

Key benefits of production management software include:

- Real-time inventory tracking: Avoid stockouts and overproduction with live data.

- Efficient production scheduling: Ensure that orders are fulfilled on time by optimizing production timelines.

- Cost control: Better visibility into costs, allowing businesses to reduce waste and manage budgets effectively.

- Increased productivity: Automation of manual tasks and data-driven decision-making reduces errors and downtime.

Factors to Consider When Choosing Software

When choosing production management software, it’s important to consider a variety of factors that will impact the software’s effectiveness in your business. Below are some key considerations to keep in mind:

-

Business Size and Industry: Ensure the software aligns with the size of your business and the complexity of your manufacturing processes. Some tools are better suited for small to medium businesses, while others are designed to handle large-scale, global operations.

-

Ease of Use: The software should be user-friendly and easy for your team to adopt. If the tool has a steep learning curve, it may take longer to implement and could affect productivity.

-

Scalability: As your business grows, your software should grow with you. Consider whether the tool can scale to meet increasing demand, production complexity, and multiple locations.

-

Integration Capabilities: Look for software that integrates easily with other business systems, such as accounting, CRM, and e-commerce platforms. Seamless integration helps ensure all departments can work from the same data.

-

Customization: Depending on your industry, you may need to customize the software to match your unique workflows. Flexible tools allow you to tailor processes and reports to fit your specific needs.

-

Pricing and Budget: Cost is always a key factor. Consider the long-term value of the software in relation to its price, and whether it provides the features you need without unnecessary extras that increase the cost.

Key Features to Look For

While each manufacturer’s needs will differ, there are some essential features that most production management software should offer:

-

Real-time Inventory Tracking: The ability to monitor inventory levels in real time is crucial for efficient production planning and avoiding stockouts or overproduction.

-

Production Scheduling: Effective production scheduling tools allow businesses to optimize their resources, meet deadlines, and reduce downtime on the shop floor.

-

Order Management: Streamline the process of receiving and fulfilling orders, ensuring that production aligns with customer demand.

-

Resource Allocation: Allocate materials, equipment, and labor efficiently to maximize productivity and minimize waste.

-

Reporting and Analytics: Data-driven insights are essential for making informed decisions, tracking KPIs, and improving overall production efficiency.

-

Integration with Other Tools: Seamless integration with accounting systems, e-commerce platforms, and CRM tools ensures that all business operations are synchronized and data flows smoothly between departments.

-

Scalability: The software should be able to grow with your business, whether that means handling more orders, expanding to new locations, or managing more complex production processes.

Making the Right Choice

To choose the best production management software for your business, start by identifying your specific needs, including the size of your business, the complexity of your production process, and your long-term goals. From there, look for software that offers the key features necessary to address those needs while remaining scalable, user-friendly, and within your budget.

-

Trial Periods: Take advantage of free trials or demos offered by software providers. This allows you to test the software’s functionality and determine whether it meets your operational requirements before committing.

-

Consult Stakeholders: Involve key team members in the decision-making process to ensure the software will be a good fit for everyone involved in production, from managers to shop floor workers.

-

Future-Proofing: Choose a solution that will not only address your current challenges but will also support future growth. This will save you from the hassle of switching to a new system down the road.

Ultimately, the right production management software should help streamline your production processes, increase efficiency, and give you the insights you need to make informed, data-driven decisions. With the reviews and guidance provided in this article, you’re now well-equipped to make the right choice for your manufacturing operations.

Conclusion

Choosing the right production management software is a critical decision for any manufacturer. With the tools reviewed in this article, manufacturers of all sizes can find a solution that fits their unique needs, whether they are looking for a user-friendly platform with customizable workflows or a robust ERP system with advanced manufacturing capabilities.

From monday.com’s flexible work management capabilities to NetSuite Manufacturing’s enterprise-level scalability, each software solution offers unique benefits that cater to different manufacturing requirements. For small businesses, tools like inFlow Inventory and Katana Manufacturing ERP provide powerful inventory management and real-time production control, while larger enterprises may benefit from the full-scale ERP functionalities of NetSuite or the flexibility of Odoo Manufacturing. Custom manufacturers can find tailored solutions in JobBOSS, which is designed to handle unique, on-demand production workflows.

In the end, the best production management software will depend on your specific business requirements, your production complexity, and the scale of your operations. Below, we’ll outline how you can make the right choice for your manufacturing needs.

FAQ

What is production management software?

Production management software is a tool designed to help manufacturers manage and streamline production processes, including inventory tracking, production scheduling, order management, and resource allocation. It integrates key functions to provide real-time insights and automation, improving efficiency and reducing errors across the manufacturing operation.

What are the most important features in production management software?

Essential features include real-time inventory tracking, production scheduling, order management, resource allocation, reporting and analytics, and integration capabilities with other tools like accounting software, CRMs, and e-commerce platforms.

Can production management software be used by small manufacturers?

Yes, there are several production management software options specifically designed for small to medium-sized manufacturers. Tools like Katana and inFlow Inventory provide scalable solutions that are easy to implement and offer affordable pricing plans, making them suitable for smaller operations.

How does production management software help with inventory control?

Production management software helps track inventory levels in real-time, providing accurate data on stock levels, materials availability, and demand forecasting. This reduces the risk of overstocking or stockouts and helps manufacturers align their production with actual inventory levels, ensuring smoother operations.

Can production management software integrate with other business systems?

Yes, many production management software options offer integration with accounting tools, e-commerce platforms, CRM systems, and ERP solutions. For example, monday.com and Katana both integrate with popular platforms like QuickBooks, Shopify, and WooCommerce, ensuring that all your business systems work together seamlessly.

What is the difference between MRP and ERP in production management software?

MRP (Material Requirements Planning) focuses on production planning, inventory control, and scheduling of raw materials. ERP (Enterprise Resource Planning) encompasses a broader range of business functions, including MRP, but also integrates financial management, human resources, supply chain management, and more. ERP is often used by larger organizations with more complex needs.

How long does it take to implement production management software?

Implementation time depends on the complexity of the software and the size of your organization. For small businesses, some tools, like inFlow Inventory or monday.com can be set up quickly in a matter of days or weeks. Larger, more complex systems like NetSuite or Odoo may take several months to fully implement and customize.

What is production planning software?

Production planning software helps manufacturers schedule and plan their production processes by allocating resources, managing materials, and setting production timelines. It ensures that production meets customer demand while optimizing resource use and minimizing downtime. Tools like Katana and MRPeasy are examples of production planning software that help streamline the manufacturing workflow.

How does production scheduling software improve manufacturing efficiency?

Production scheduling software optimizes the allocation of resources, machinery, and labor to ensure that production tasks are completed on time. By automating scheduling, manufacturers can reduce bottlenecks, improve on-time delivery, and make real-time adjustments to avoid delays. JobBOSS and NetSuite Manufacturing are examples of software that offer advanced production scheduling capabilities.

What are the benefits of using manufacturing management software?

Manufacturing management software provides a comprehensive solution for overseeing all aspects of the manufacturing process, from inventory control to production scheduling and order management. It improves visibility across the entire production cycle, reduces manual errors, and allows for better resource allocation. Tools like Odoo Manufacturing and Fishbowl Manufacturing help businesses manage operations more efficiently by integrating various production processes into one system.

What are some affordable production management software options for small businesses?

Affordable options for small businesses include Katana Manufacturing ERP, inFlow Inventory, and Fishbowl Manufacturing. These solutions offer flexible pricing plans and essential features like inventory management and production scheduling, making them cost-effective choices for small to medium-sized manufacturers.